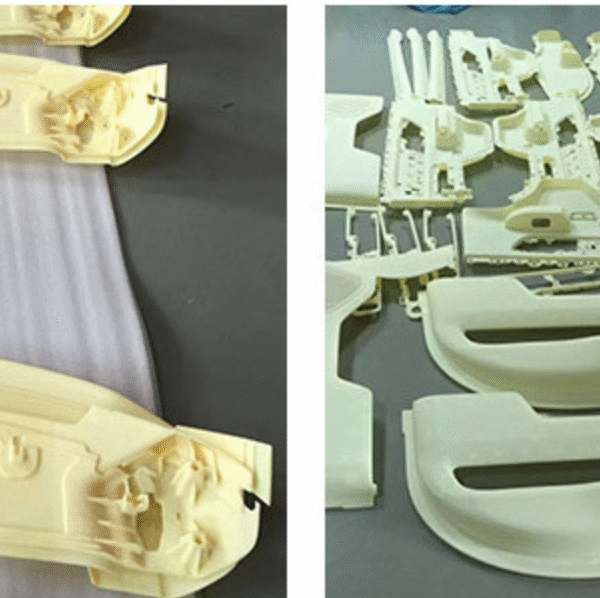

3D printed products

You're welcome to send me the photos and drawings of the products and equipment you need.

I'll provide you with a quotation.

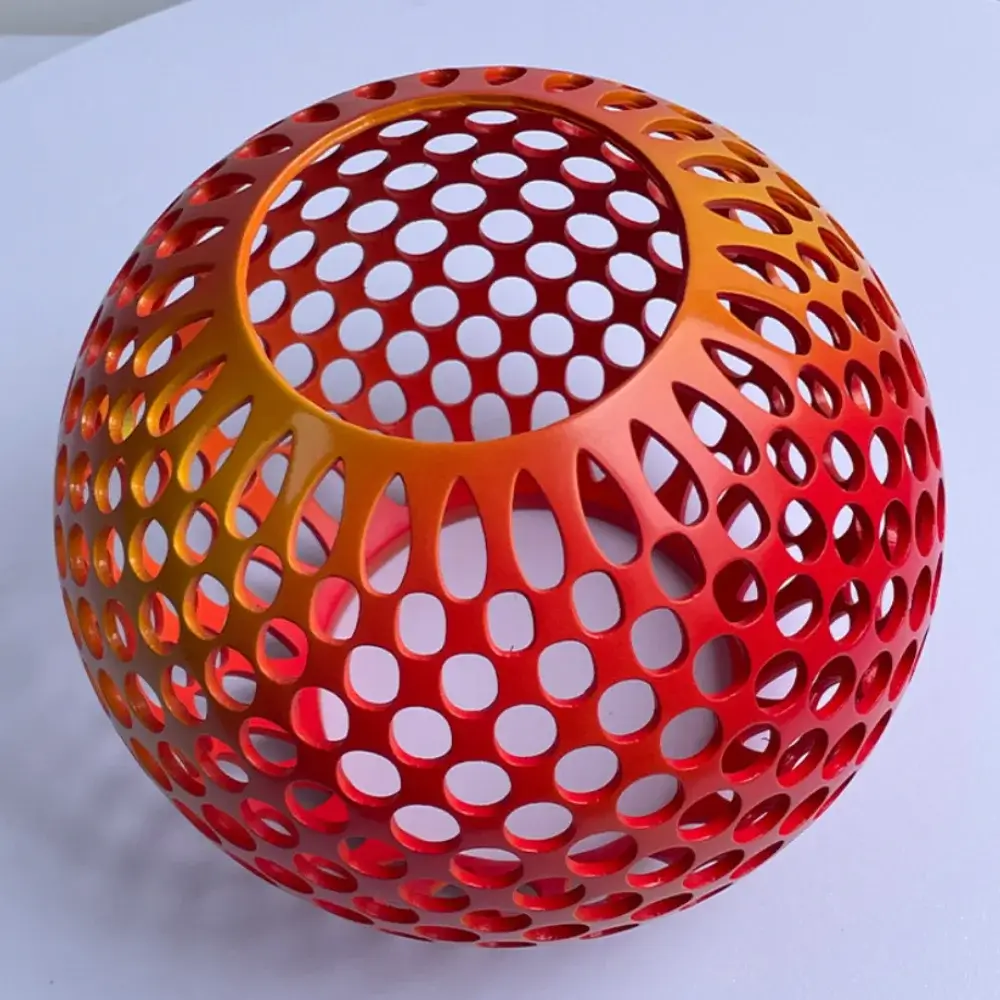

3D printing is an additive manufacturing technology. It creates objects by stacking materials such as plastics, metals, and resins layer by layer based on digital models through processes like fused deposition, photopolymerization, and laser sintering.

It has a wide range of applications. In manufacturing, it is used for quickly making product prototypes and for customized and small-batch production of parts. In the medical field, it can print human organ models to assist in surgery and customize prosthetics and braces. In the construction industry, it can make architectural models and components. In the art and culture field, it helps with artistic creation and cultural relic restoration. In education, it is used to make teaching models and support students’ innovative practice.

Category: 3D Printing

Description

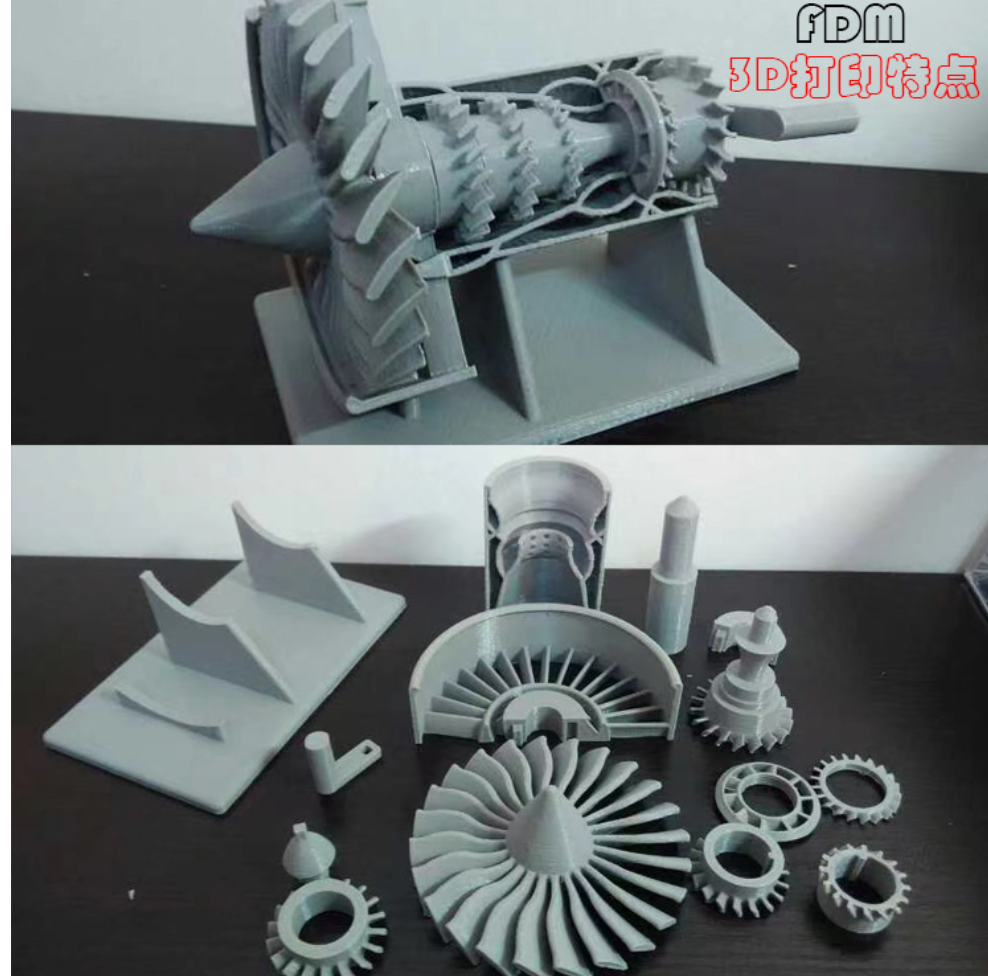

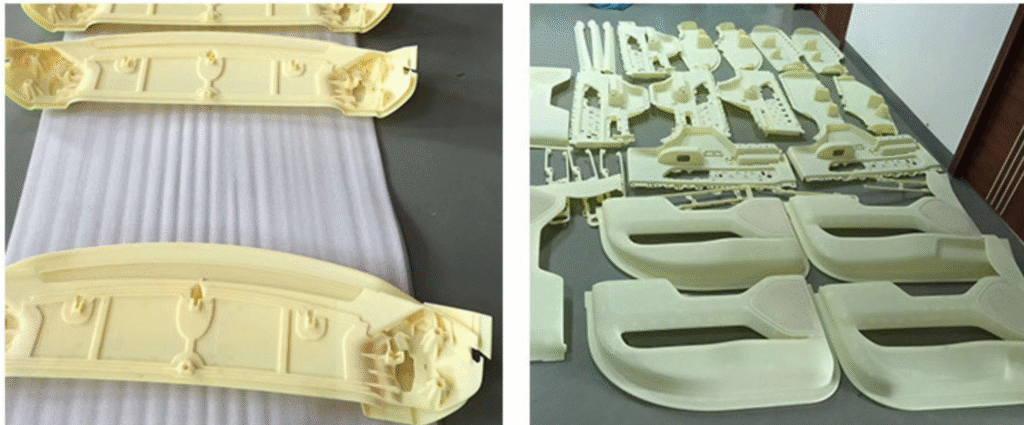

3D – Printed Aircraft Engine Model and Components

This aircraft engine model and components are produced via Fused Deposition Modeling (FDM) 3D printing technology, making them an ideal choice for model making and component research and development in the aviation field.

Advanced Manufacturing Technology: Utilizing FDM 3D printing technology, it can accurately replicate the complex internal and external structures of aircraft engines. From the fine curved surfaces of turbine blades to the precise structure of engine cavities, every detail is clearly presented, ensuring a high degree of simulation for the model and components.

High – Quality Materials: High – performance thermoplastic materials that meet relevant American quality standards are selected. They have excellent durability, impact resistance, and high – temperature resistance. Even when used for long – term display or in teaching and simulation experiments, they are not easily deformed or damaged and can maintain good appearance and performance.

Versatile Uses: For aviation and aerospace enthusiasts, museums, and educational institutions, the complete aircraft engine model is an excellent display item and teaching aid, helping audiences and students better understand the working principle and structure of aircraft engines intuitively. The disassembled components are suitable for professional aviation colleges and research institutions to conduct component research, assembly practice, etc., facilitating the development of scientific research and teaching work.

Customization Service: We also provide customization services. According to your specific needs, such as adjusting the model size and modifying the design details of components, we can quickly and efficiently create exclusive 3D – printed aircraft engine – related products for you. Whether for commercial display, academic research, or personal collection, our products can meet your diverse needs in the US market

Customer Reviews

Rated 0 out of 5

0 reviews

Rated 5 out of 5

0

Rated 4 out of 5

0

Rated 3 out of 5

0

Rated 2 out of 5

0

Rated 1 out of 5

0

Be the first to review “3D printed products” Cancel reply

Related Products

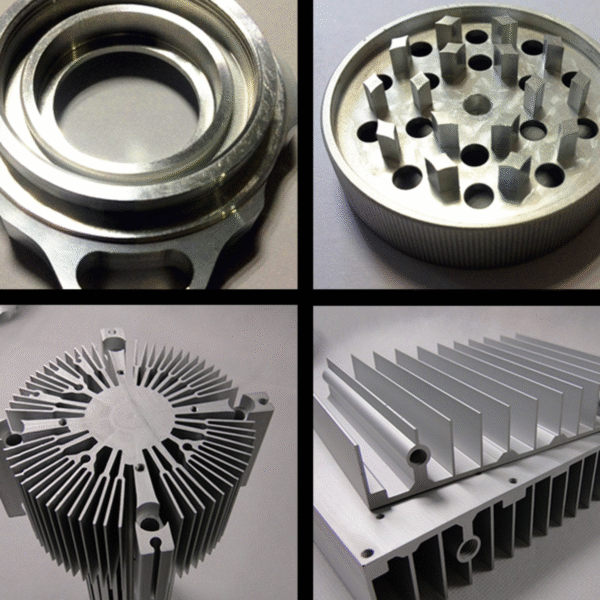

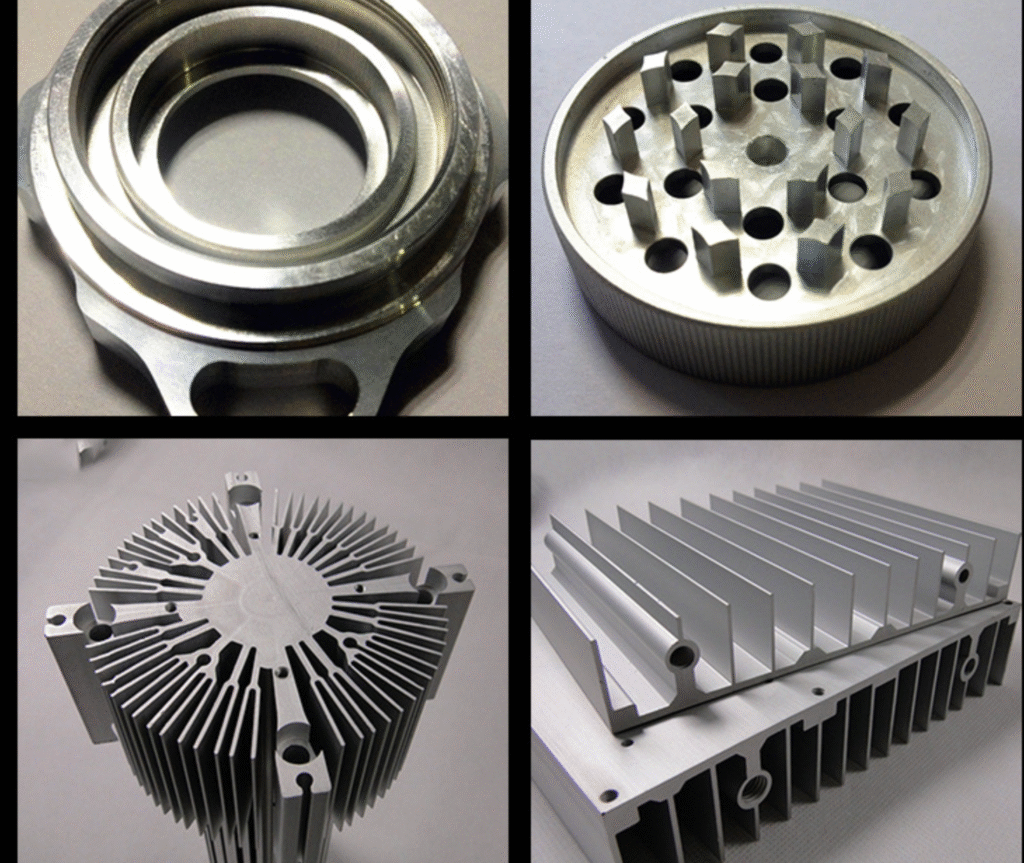

RAPIDPROTOTYPING SERVICES

Samshion offers rapid prototyping services to turn your digital designs into fully functional prototypes with unmatched speed and accuracy. Our in-house capabilities include precisioncNc machining,3D printing.vacuum casting, sheet metal prototyping, and rapid tooling - all designed to support fast design validation and iterative development.

RAPID MANUFACTURING SOLUTIONS

Samshion provides scalable, cost-effective manufacturing solutions - bridging the gap between prototyping and full-scale production. Our services include production-grade cNc machining, plastic injection molding, die casting, sheet metal fabrication, and post-processing.

Reviews

Clear filtersThere are no reviews yet.